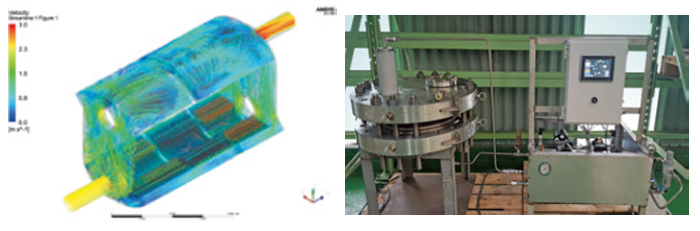

Plate&Shell Heat Exchanger

Product overview (purpose)

PSHE(Plate&Shell Heat Exchanger) is one of the compact type of heat exchanger available as alternatives to Shell&Tube Heat Exchanger or Plate Heat Exchanger(PHE). Its name is derived from the structure that a fully welded plate pack is enclosed in a cylindrical shell.

Because of its special structure and manufacturing method, PSHE can combine the advantage of Shell&Tube Heat Exchanger(high stiffness)and that of PHE(high heat-transfer efficiency and compact size), and also can be designed and manufactured for any operation condition.

TANKTECH’s PSHE has already tested and delivered for cryogenic services such as LNG or LN2 handling process. Therefore, it can be a highly competitive solution for LNG vaporizer, BOG heater and so on.

Because of its special structure and manufacturing method, PSHE can combine the advantage of Shell&Tube Heat Exchanger(high stiffness)and that of PHE(high heat-transfer efficiency and compact size), and also can be designed and manufactured for any operation condition.

TANKTECH’s PSHE has already tested and delivered for cryogenic services such as LNG or LN2 handling process. Therefore, it can be a highly competitive solution for LNG vaporizer, BOG heater and so on.

Technology of TANKTECH

Shell and Plate Design

Manufacturing

Fatigue Resistance/Pressure Testing

Performance Test & Inspection

Advantages

High pressure and cryogenic to high temperature capability.

- It has a round, fully welded construction.

- Strong structure and applicable to various temperatures by welding.

- It has a round, fully welded construction.

- Strong structure and applicable to various temperatures by welding.

Compact size

- TKT PSHE are approx. 50% smaller than traditional shell & tube heat exchangers because of higher heat transfer area created by the corrugated patterns of their plates

- TKT PSHE are approx. 50% smaller than traditional shell & tube heat exchangers because of higher heat transfer area created by the corrugated patterns of their plates

Gasket-free construction

- The gasket-free construction is durable enough for the harshest conditions and prevents maintenance issues and no leakages in very high/low pressures and temperature.

- The gasket-free construction is durable enough for the harshest conditions and prevents maintenance issues and no leakages in very high/low pressures and temperature.

Easy maintenance

- Turbulent flow even at low velocities, keeping the plates free from scaling and fouling longer than the laminar flow in shell and tube units.

- Easy to maintain due to the option for removable plate pack core via a bolted cover on one end of the shell [Openable Type].

- Turbulent flow even at low velocities, keeping the plates free from scaling and fouling longer than the laminar flow in shell and tube units.

- Easy to maintain due to the option for removable plate pack core via a bolted cover on one end of the shell [Openable Type].

Related images